Pawsome-Specializing in vet health products since 2015

Pawsome-Specializing in vet health products since 2015

The market for Hand Held Vibrating Saw models is rapidly evolving, with projections indicating a growth rate of over 10% annually through 2026. According to a recent industry report by J.D. Haverford, a leading analyst in cutting tools, precision cutting has never been more critical. Haverford emphasizes, “The right tool can transform the efficiency of precision tasks.” This statement underscores the importance of selecting high-quality hand-held vibrating saws.

The advancements in technology have led to innovative features in these saws. Enhanced vibration control, lightweight designs, and improved blade compatibility are just a few examples. Industry data reveals that professionals prefer saws that balance power and flexibility for various cutting tasks. Users report heightened accuracy when using modern models, but challenges remain. Not all products deliver the promised performance, which can lead to user frustration.

In this context, understanding the specifications and capabilities of top models is crucial. Various factors, such as motor power and ergonomic design, impact the effectiveness of a Hand Held Vibrating Saw. Evaluating these aspects helps in making informed choices. The industry is not without its flaws; some brands lack thorough customer support, making it difficult for users to address issues. As we explore the best models of 2026, these insights will guide professionals toward better tools for their projects.

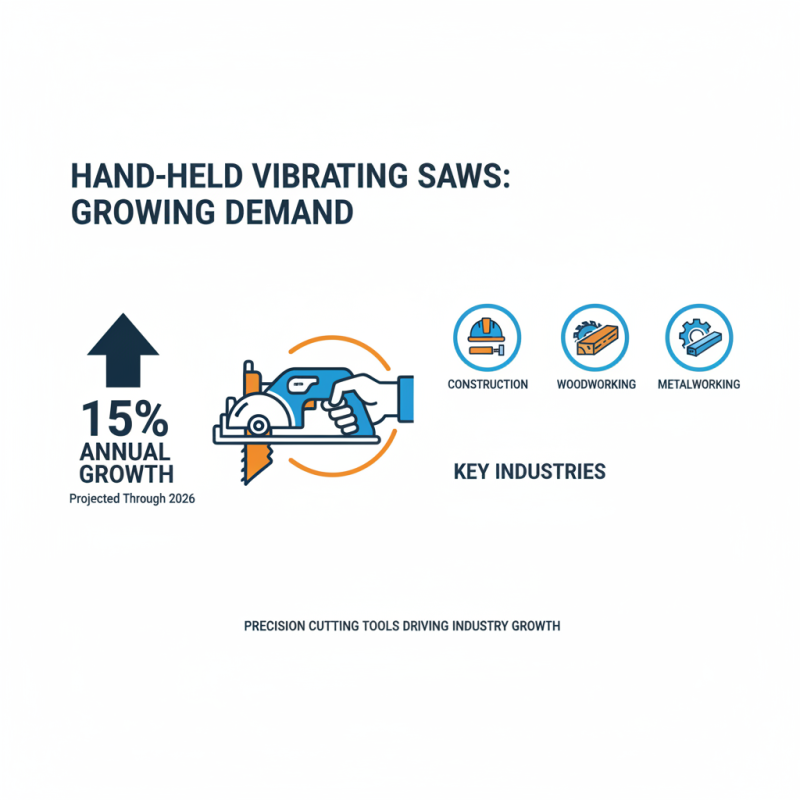

Hand-held vibrating saws have become indispensable in various industries. These tools excel in precision cutting, making them a favorite among contractors and DIY enthusiasts. Recent industry reports reveal that the demand for such saws is projected to grow by over 15% annually through 2026. This increase highlights their importance in sectors such as construction, woodworking, and metalworking.

The versatility of hand-held vibrating saws allows for intricate cuts in different materials. They are particularly effective in tight spaces where larger tools cannot reach. Many professionals rely on them for tasks like trimming edges or creating detailed patterns. However, improper use can lead to poor cuts and safety hazards. Operators must be mindful of their technique to avoid accidents and ensure accuracy.

While the technology behind these saws has advanced, there are still areas needing improvement. Battery life remains a concern, as extended use may drain power quickly. Additionally, vibrations can lead to user fatigue, affecting performance over time. Addressing these issues will significantly enhance the user experience and increase productivity in various applications.

When selecting a hand-held vibrating saw, key features play a vital role. The weight and balance of the saw affect comfort during use. A heavier model may lead to fatigue. However, a lightweight saw might not provide the necessary power for tougher jobs. Users should try models firsthand to gauge comfort.

The blade type is another crucial aspect. Different blades serve various materials. Some may cut through wood without issue, while others are better for metal. Check the compatibility of blades with specific projects. Pay attention to the depth of cut as well. A deeper cut can be essential for certain tasks.

Tips for making a wise choice: consider the vibration reduction technology. It helps to minimize hand fatigue. Look for ergonomic designs that offer a secure grip. Always read user reviews for real-world insights. A versatile saw can add value to your toolkit. But finding the perfect model may take time and patience.

When it comes to handheld vibrating saws, precision is key. The 2026 models on the market offer a range of features tailored for accurate cutting. These saws are designed to provide cleaner cuts, whether you are working with wood, metal, or plastic. The lightweight nature of these tools allows for easy maneuverability, making them ideal for tight spaces.

Tips: Always ensure the blade is sharp. A dull blade can lead to uneven surfaces. Take your time with intricate cuts. Rushing may result in mistakes.

The latest models prioritize user comfort. Ergonomic handles reduce strain during extended use. Some saws come with vibration dampening technology, increasing precision and control. However, not all users find these features equally effective. It's a good idea to test several models before committing.

Tips: Experiment with different cutting speeds. Slower speeds often yield better control, especially for delicate tasks. Practice on scrap materials to build confidence. It's normal to make mistakes while learning.

When it comes to hand-held vibrating saws, user reviews reveal a wealth of information. Many users appreciate the lightweight design. It makes cutting through various materials easier. Some models excel in precision, carving intricate shapes. However, not all models have smooth operation. Users report some saws are hard to maneuver in tight spots.

Performance ratings vary widely among different models. Some receive high praise for durability. Users mention they stand up to heavy use without losing power. Yet, others struggle with overheating during extended jobs. A few sawing experiences fell short of expectations. Blade changes can be inconvenient for some models. A seamless experience is often more ideal.

In terms of user feedback, comfort is key during lengthy projects. A well-balanced saw reduces fatigue significantly. However, some users still find vibrations uncomfortable. This indicates a gap in design. Better grip and ergonomic features could enhance overall usability. Finding the right model requires careful consideration and personal testing.

Hand-held vibrating saws are essential tools for precision cutting. To maintain their performance, proper care is crucial. Studies indicate that regular maintenance can extend a tool’s life by up to 30%. Many users overlook basic upkeep, which can lead to decreased accuracy. A simple tip is to keep the blade clean and free from debris, which can affect cutting quality.

Vibration can cause wear over time. According to recent data, 20% of users report issues due to lack of maintenance. Inspecting saw components regularly ensures smooth operation. Tightening bolts and lubricating moving parts can prevent significant damage. It’s vital to check the battery life and charging systems. Neglecting these aspects can lead to unexpected power loss during usage.

Additionally, using the right cutting technique matters. Poor techniques not only wear down a blade, but also create safety risks. Frequent users should consider keeping a maintenance log. Documenting upkeep helps track performance trends. This practice can reveal patterns that indicate when a tool needs servicing. Remember, investing time in maintenance now can save costs and enhance productivity later.