Pawsome-Specializing in vet health products since 2015

Pawsome-Specializing in vet health products since 2015

In the realm of masonry, innovation never stops. The Oscillating Masonry Saw stands out among other tools, making tasks simpler and more efficient. Expert craftsman John Smith states, “Using an oscillating saw can change the way you approach masonry projects.” His insight captures the essence of this remarkable tool.

The Oscillating Masonry Saw offers unique benefits in various construction tasks. Its design allows for precise cuts, making it a favorite among professionals. This tool not only enhances accuracy but also boosts productivity on the job site. Moreover, its ability to cut through tough materials without creating dust is a game-changer.

However, it's essential to reflect on its usage. Some users report initial challenges in mastering its operation. The learning curve can lead to errors, but the payoff is worth it. Adapting to this tool might take time, but understanding its advantages can significantly improve project outcomes. Exploring these benefits helps both novices and experts elevate their craftsmanship.

Using an oscillating masonry saw offers many benefits, especially when it comes to precision. The design of these saws allows for intricate cuts in various materials, from concrete to brick. Enhanced cutting control means you can create cleaner edges and more detailed patterns. This is crucial for artists and builders alike. You won't waste materials due to inaccurate cuts.

Tips: Keep a steady hand while cutting. A firm grip will ensure better accuracy. Don't rush; slow movements often yield the best results.

Another great benefit is the ability to adjust the depth of your cuts. This feature allows for layering and mosaic designs. You can create unique textures in your projects. However, practice is necessary. You may encounter uneven cuts at first. Analyzing each cut helps you improve over time.

Tips: Always measure twice before cutting. A single miscalculation can ruin your work. Make use of test pieces to refine your technique.

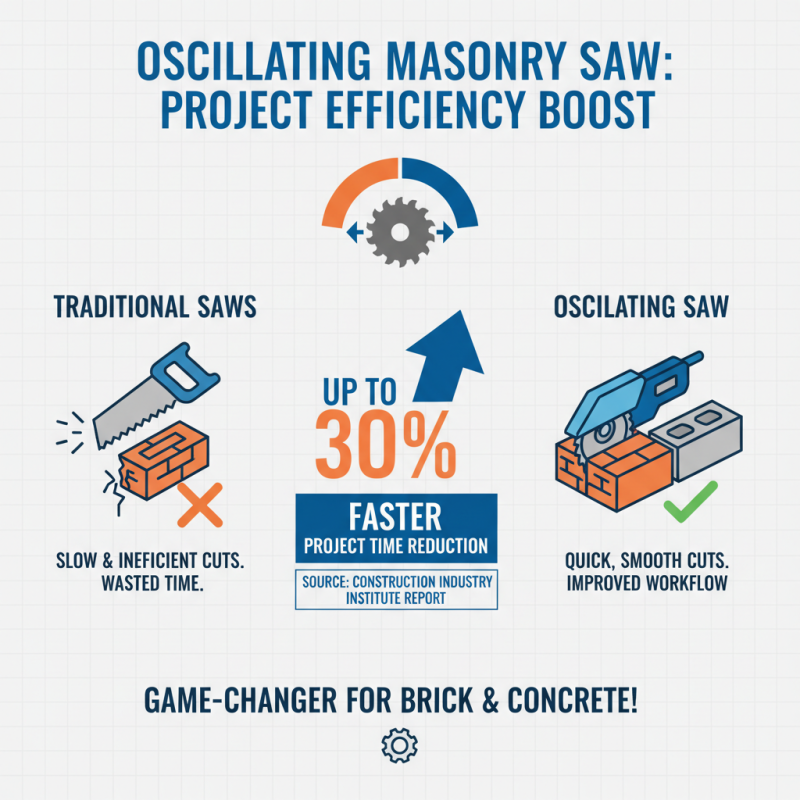

An oscillating masonry saw is a game-changer for construction projects. It enhances efficiency significantly. According to a report by the Construction Industry Institute, optimal tool usage can reduce project time by up to 30%. This is especially true when cutting materials like brick or concrete. Traditional saws can struggle and waste valuable time. An oscillating saw cuts quickly and smoothly, improving workflow.

The improved precision of these saws also cuts down on errors. Less rework means more savings. A study shows that labor costs can account for around 50% of total project expenses. A tool that reduces mistakes will consequently lower costs. However, not all users leverage these benefits. Some still stick to outdated methods, hampering their productivity.

Moreover, the setup time can sometimes be lengthy. Not all operators are familiar with oscillating saws. Training might be necessary. This could slow down initial project phases. Yet, once mastered, the saw can transform work dynamics into a highly efficient process. Adopting new technology takes time, but the long-term benefits can outweigh these initial roadblocks.

An oscillating masonry saw stands out for its effectiveness in cutting various materials. One significant benefit is reduced material waste. Traditional cutting methods often result in significant loss of valuable materials. Studies indicate that improved cutting accuracy can reduce waste by up to 30%. This means more of your investment goes into your project and less into the landfill.

Cost efficiency is another highlight. With reduced waste, projects become financially viable. The initial investment in an oscillating masonry saw pays off quickly. For instance, a report from the National Association of Home Builders indicates that efficient tools can lower project costs by approximately 20%. This efficiency creates a strong incentive to adopt modern cutting techniques.

Tips for using an oscillating masonry saw effectively include ensuring blades are appropriate for the material. Regular maintenance of the saw can also enhance cutting precision. Remember to secure materials properly to avoid accidents. As with any tool, there is a learning curve. Tweak your cutting methods as you gain experience. Reflection can lead to better techniques and even more savings on your next project.

When working on masonry projects, having the right tools can make all the difference. An oscillating masonry saw is versatile, making it suitable for a variety of materials like brick, concrete, and tile. This flexibility is essential for achieving precise cuts, especially when working on intricate designs. According to industry reports, using the right saw can increase cutting efficiency by up to 30%.

Tip: Always choose the correct blade for the material you plan to cut. This can significantly affect cutting quality and speed.

The oscillating feature allows for better control, reducing the risk of material damage. Additionally, it minimizes dust and debris, creating a cleaner workspace. However, not all oscillating saws perform equally. Some may struggle with denser materials. It’s crucial to match your project needs with the saw's capabilities. Many professionals recommend testing different models before committing.

Tip: Regularly maintain your saw to ensure optimal performance. Dull blades waste time and can lead to inaccuracies. A little preventive care goes a long way.

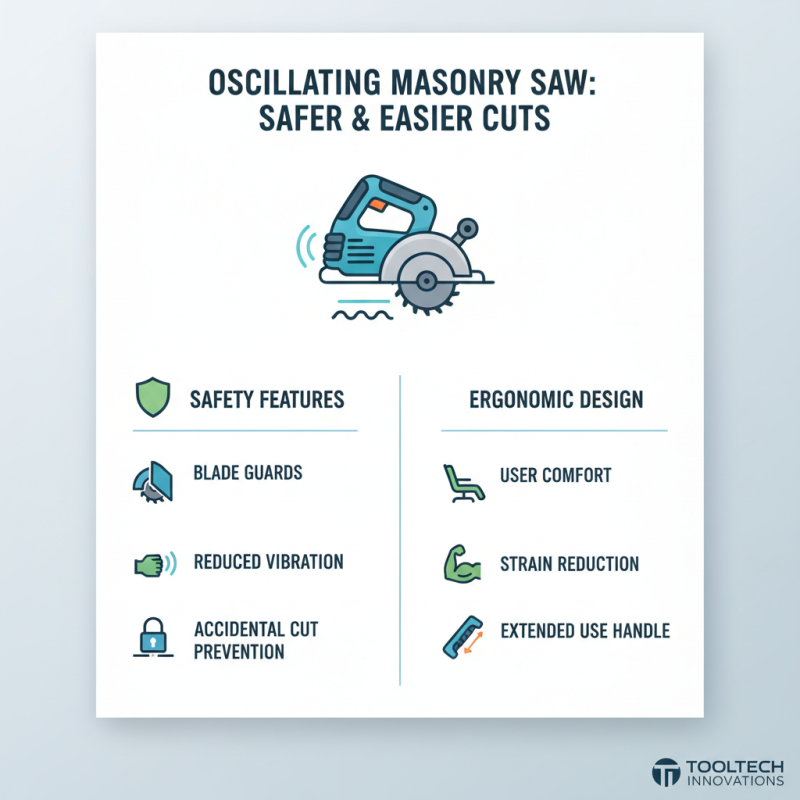

Using an oscillating masonry saw provides significant safety features and ergonomic designs aimed at user comfort. These tools often come with guards that minimize the risk of accidental cuts. The vibrations are dampened, making operations easier and safer. A well-designed handle can significantly reduce strain during extended use.

Comfort is key for long tasks. Look for saws with padded grips and adjustable handles. This helps maintain a steady grip and reduces fatigue. Ensuring your workspace is clear also makes a difference. A clutter-free area means fewer chances of accidents. Using proper eye and ear protection is crucial as well.

Tip: Always check the blade before use. A dull blade can lead to more strain. Stay mindful of your posture. Keeping a straight back while working can prevent long-term discomfort. Adjusting the height of your workspace helps in achieving this. Taking breaks can also prevent strain. Regularly stretching your hands and arms is a good practice. Small changes can lead to significant comfort improvements.