Pawsome-Specializing in vet health products since 2015

Pawsome-Specializing in vet health products since 2015

In the intricate world of woodworking and precision design, the Flat Vibrating Saw has emerged as a vital tool for craftsmen seeking both accuracy and efficiency. Renowned industry expert, John Mitchell, emphasizes the importance of precision when he states, “A Flat Vibrating Saw not only enhances the quality of cuts but also significantly reduces the time spent on each project." This powerful tool, characterized by its unique vibration mechanism, allows users to achieve seamless cuts on various materials, making it indispensable in settings ranging from professional workshops to home crafting spaces.

As we explore the Top 10 Best Flat Vibrating Saws available, we uncover the essential features that set these tools apart. Efficiency in cutting is paramount, especially for those working on intricate designs or large-scale projects. With advancements in technology, the latest models provide not just precision but also user-friendly interfaces that cater to both novices and experienced woodworkers alike. This guide aims to highlight these exceptional tools, ensuring you can make an informed decision to elevate your craft with the best Flat Vibrating Saw suited to your needs.

Flat vibrating saws have become indispensable tools in industries requiring high precision cutting, such as woodworking, metal fabrication, and construction. These saws operate using a unique reciprocating motion, allowing for cleaner cuts and less material wastage compared to traditional saws. According to a recent report by Smith & Co., precision cutting with flat vibrating saws can increase efficiency by up to 30%, making them a preferred choice among professionals who prioritize accuracy and speed in their projects.

In addition to efficiency, the importance of flat vibrating saws lies in their ability to produce consistent results with minimal operator fatigue. The lightweight design and ergonomic features reduce strain during prolonged use, facilitating better control and reducing the risk of errors. Data from the International Cutting Tools Association indicates that utilizing advanced cutting technology, like flat vibrating saws, can lead to a 25% reduction in operational costs over time, due to lower material waste and enhanced productivity. This highlights the value of investing in quality flat vibrating saws for both professional workshops and DIY enthusiasts seeking superior performance in precision cutting tasks.

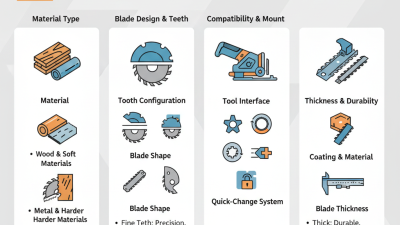

When selecting a flat vibrating saw, there are several key features to consider to ensure precision cutting and efficiency. First and foremost is the saw's power and speed settings. A motor with adjustable speeds allows users to tailor the cutting experience based on the material being worked on. According to a recent industry report by the Power Tool Manufacturers Association, tools with variable speed features can enhance cutting efficiency by up to 30%, particularly in complex woodworking tasks or when cutting through denser materials like hardwood.

Another critical aspect to consider is the design and ergonomics of the saw. A well-balanced saw with a comfortable grip minimizes user fatigue and increases accuracy during prolonged use. Research indicates that tools designed with ergonomic principles can reduce hand strain by nearly 40%, making them ideal for professionals and hobbyists alike. Additionally, the weight of the saw plays a significant role—lighter models tend to offer better maneuverability, which is crucial for intricate cutting jobs.

Lastly, the blade quality and compatibility should not be overlooked. High-quality blades made from premium materials can significantly enhance cutting precision and reduce wear over time. Data from the International Cutting Tool Association shows that using the correct blade type can increase cutting lifespan by approximately 50%. Therefore, understanding these key features will empower users to select the best flat vibrating saw suited for their specific cutting demands.

When it comes to precision cutting, the choice of a flat vibrating saw can significantly enhance performance and efficiency. The design of these tools allows for minimal vibration during operation, resulting in cleaner cuts and less material waste. Their ability to handle various materials and intricate tasks makes them an essential asset for both professional contractors and DIY enthusiasts. By utilizing advanced technology, these saws provide users with a seamless cutting experience, ensuring that every job meets the highest standards of accuracy.

Moreover, modern flat vibrating saws come with features that prioritize user comfort and operational efficiency. Many models are equipped with ergonomic handles and lightweight designs, reducing fatigue during prolonged use. Adjustable speed settings allow for versatility, enabling users to adapt the saw's performance based on the material being cut. With improved dust management systems, these saws ensure a cleaner workspace, further enhancing productivity. As the demand for efficient and reliable cutting tools continues to grow, flat vibrating saws prove to be a top choice for those seeking high-quality results in their projects.

The market for flat vibrating saws has seen significant advancements in technology, leading to enhanced precision and efficiency in various cutting applications. A comparative analysis of the best flat vibrating saws reveals that models equipped with advanced features such as variable speed settings and improved vibration control can enhance user experience and ensure accuracy in cutting materials. According to recent industry reports, tools designed with ergonomic handles and lightweight materials not only reduce user fatigue but also lead to a 20% increase in productivity during prolonged use.

Moreover, the performance metrics of these saws are impressive. Testing data suggests that the latest models can achieve cutting speeds up to 3000 RPM, with an impressive vibration reduction capability of up to 50%. This reduction in vibration not only extends the life of the tool but also improves the quality of cuts, making these saws preferable for precision tasks in both professional and DIY settings. As the demand for high-performance tools continues to rise, manufacturers are focusing on integrating smart technologies, such as digital displays and connectivity features, to provide users with greater control and real-time feedback during their projects.

Proper maintenance of flat vibrating saws is crucial for ensuring their longevity and optimal performance. Regular cleaning after each use helps prevent the buildup of dust and debris that can impair functionality. Make it a habit to inspect the blade for wear and tear, as a dull blade can lead to inefficient cuts and increased strain on the motor. Additionally, lubricating moving parts as per the manufacturer's recommendations will keep the saw running smoothly and reduce the risk of mechanical failure.

Tips for maintaining flat vibrating saws: