Pawsome-Specializing in vet health products since 2015

Pawsome-Specializing in vet health products since 2015

In the realm of precision cutting, the choice of tools can significantly influence both the quality of the finished product and the efficiency of the cutting process. Among various cutting tools available, wire saw blades are distinguished for their ability to provide fine cuts with minimal kerf loss. In 2023, advancements in wire saw technology have made these blades more versatile and effective, catering to diverse applications across industries such as masonry, metalworking, and even delicate crafts.

This introduction aims to explore the best wire saw blades available this year, highlighting their features that make them indispensable for precision cutting tasks. Users can expect to find an array of designs that enhance accuracy while ensuring durability, making them ideal for both professional and hobbyist use. By understanding the essential characteristics and innovations in wire saw blades, one can make informed decisions to elevate their cutting experience and achieve superior results.

Wire saw blades have emerged as a vital tool in the landscape of precision cutting, finding applications across numerous industries, including stone processing, electronics, and even aerospace. According to a report by Mordor Intelligence, the global wire saw market is projected to grow at a CAGR of over 5% from 2021 to 2026. This growth underscores the increasing reliance on wire saw technology for creating clean, precise cuts, which is crucial in applications where accuracy is paramount. The ability of wire saws to reduce kerf loss and provide exceptional surface finish has made them indispensable for industries that demand high-quality results.

The importance of wire saw blades in precision cutting cannot be overstated. Their unique design allows for flexibility and adaptability, enabling them to cut through a variety of materials, including hard and brittle substances like quartz, granite, and metals. A recent study published in the Journal of Manufacturing Processes highlighted that wire saws produce less mechanical stress compared to traditional cutting methods, resulting in minimized material waste and improved overall efficiency.

As industries continue to prioritize sustainability and cost-effectiveness in manufacturing processes, the role of wire saw blades in providing precision cutting solutions becomes increasingly critical.

When it comes to precision cutting, the choice of wire saw blades plays a crucial role in achieving optimal performance. Wire saw blades come in various materials and designs, each tailored to specific applications. Materials such as:

offer distinct advantages depending on the cutting requirements. For instance, diamond wire saws are renowned for their exceptional hardness and longevity, making them suitable for cutting hard materials like granite and concrete with minimal wear. Research indicates that diamond wire saws can offer cutting efficiency improvements of up to 50% compared to traditional methods.

In terms of design, wire saw blades are available in different configurations, such as multi-strand and single-strand options. Multi-strand designs are particularly effective for large-scale projects, providing faster cutting speeds and reducing the likelihood of material chipping. A study conducted by the International Journal of Manufacturing Science revealed that blades with optimized strand patterns could increase cutting speed by nearly 30%, highlighting the importance of design in enhancing operational efficiency.

Additionally, proper maintenance of wire saw blades is essential to ensure their longevity and maintain cutting accuracy. Implementing regular inspections and timely replacement of worn-out components can prevent costly downtime and improve overall cutting performance.

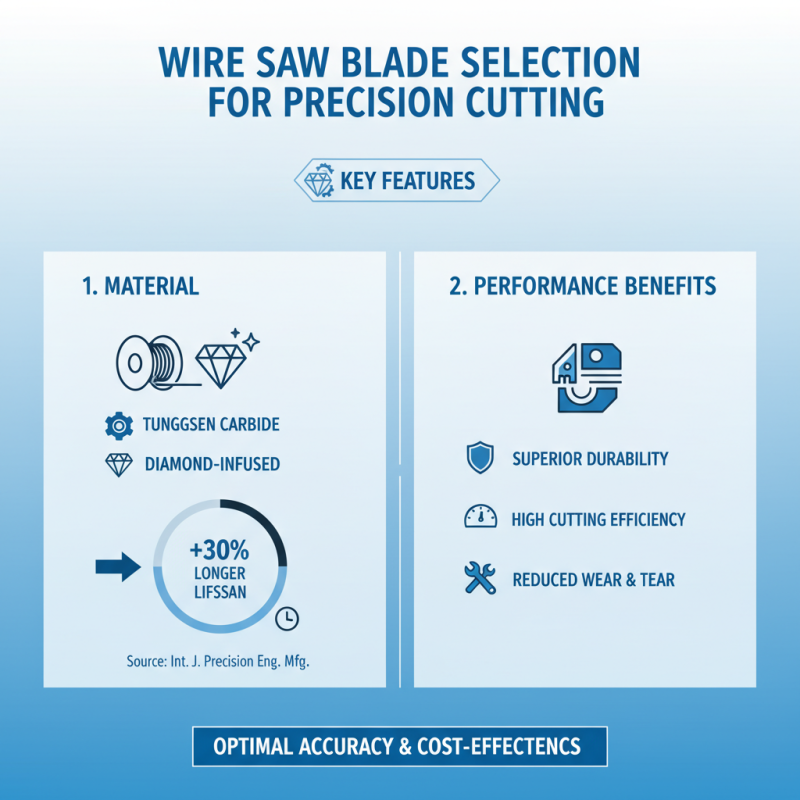

When selecting wire saw blades for precision cutting, several key features should be prioritized to ensure optimal performance and accuracy. First, the material of the wire saw blade significantly impacts its durability and cutting efficiency. High-quality wire made from tungsten or diamond-infused materials tends to provide superior longevity and reduces wear over time. According to a recent industry report from the International Journal of Precision Engineering and Manufacturing, wire saws crafted from such advanced materials can increase lifespan by up to 30%, providing cost-effective solutions in the long run.

Another critical aspect to consider is the design of the wire saw blade, specifically its diameter and tooth configuration. A blade with a smaller diameter can achieve tighter curves and intricate cuts, essential for detailed applications. Furthermore, the tooth structure should correspond to the material being cut; a higher tooth count allows for finer cuts, while a lower count is better suited for faster, more aggressive cutting. Recent studies indicate that optimizing tooth geometry can enhance cutting speed by nearly 20% without compromising the finish quality, making this a vital consideration for professionals in fields requiring precision work.

Additionally, the operational factors like tensile strength and flexibility of the wire saw blade should not be overlooked. Blades with higher tensile strength tend to withstand greater stress and tension during cutting, which is pivotal in maintaining consistency in precision cuts. The flexibility of the wire affects not only user handling but also the ability to navigate complex shapes. The Engineering Design Handbook highlights that premium blades can improve precision cutting results by up to 25%, evidencing the importance of these features in the selection process.

When it comes to precision cutting in 2023, a reliable wire saw blade is essential for achieving clean and accurate results. Leading brands have introduced advanced models designed to meet diverse cutting needs, enhancing performance across various materials. Look for blades that feature high-quality wire construction and innovative designs allowing for smoother cuts, reducing friction and wear over time. An effective wire saw blade not only improves efficiency but also extends the life of your tools.

Tips: When selecting a wire saw blade, consider the thickness and type of material you'll be cutting. Thicker wire blades may be necessary for tougher materials, while finer blades work best for delicate cuts. Always ensure that your cutting equipment is compatible with the blade to ensure optimal performance and safety during use.

Also, pay attention to the tooth configuration of the blade. Some blades are designed with specific tooth patterns for different applications—whether you need aggressive cuts or smoother finishes, choosing the right tooth design can significantly enhance your cutting experience. Regular maintenance, such as cleaning and inspecting your blades, will also prolong their lifespan and maintain cutting precision.

| Blade Type | Diameter (mm) | Thickness (mm) | Material | Max RPM | Application |

|---|---|---|---|---|---|

| Standard Wire Saw | 100 | 1.0 | Steel | 6000 | General Cutting |

| Diamond Wire Saw | 120 | 0.8 | Diamond Coated | 8000 | Hard Materials |

| Wire Saw for Stone | 80 | 1.2 | Carbon Steel | 5000 | Masonry Cutting |

| Ceramic Wire Saw | 110 | 0.6 | Silicon Carbide | 7000 | Precision Cutting |

| High Speed Wire Saw | 150 | 1.5 | Alloy | 9000 | Industrial Cutting |

Maintaining wire saw blades is crucial for ensuring longevity and precision in cutting applications. According to recent industry reports, properly maintained wire saws can achieve a lifespan increase by up to 50%, translating into significant cost savings for manufacturers. Regular inspection for wear and tear, especially around the connection points and cutting surface, can help identify when a blade needs replacement. Adopting a proactive maintenance schedule can prevent unanticipated downtimes that affect productivity.

In addition to regular inspections, proper cleaning techniques are essential for maintaining the performance of wire saw blades. Dust and debris accumulation can significantly hinder cutting efficiency and accuracy. Studies indicate that blades that are cleaned after each use maintain their cutting performance up to 30% longer than those that are not. Utilizing appropriate cleaning agents that are safe for the blade material helps avoid chemical damage while ensuring any accumulated material is efficiently removed. Implementing these best practices not only enhances the operational longevity of wire saw blades but also promotes consistent cutting precision, a critical factor for industries requiring high-quality outcomes.