Pawsome-Specializing in vet health products since 2015

Pawsome-Specializing in vet health products since 2015

In the world of precision cutting, Wire Saw Wire has become an essential tool. Experts like Dr. John Smith, a leading figure in this industry, emphasize its importance. He once said, "Choosing the right Wire Saw Wire can transform your cutting process." This statement highlights the critical nature of quality in this field.

Many professionals face challenges when selecting Wire Saw Wire. The variety can be overwhelming, as different applications require specific characteristics. The wrong choice can lead to inefficiencies and subpar results. The precision that Wire Saw Wire offers is vital for industries such as manufacturing and construction.

Understanding the options available can be daunting. Not all Wire Saw Wires are created equal. Factors such as wire diameter, material, and flexibility play significant roles in performance. Those in the industry must navigate these choices carefully. Each decision can lead to enhanced accuracy or wasted resources. Therefore, thorough research and expert advice are crucial for optimal results in Wire Saw Wire applications.

Wire saw technology has revolutionized precision cutting in various industries. It's popular in ceramics, stone cutting, and even in silicon wafer production. A recent industry report noted that precision cutting accounts for nearly 50% of wire saw applications. This highlights the technology's significance in achieving clean cuts with minimal material waste.

The mechanics behind wire saws involve using fine wire strands, usually coated with diamond or other abrasives. This design allows intricate cuts with reduced kerf loss. Studies show that the right wire thickness can influence cut quality and speed. For instance, a thinner wire can better navigate complex shapes, but it might wear out faster. Operators often face challenges in optimizing the balance between wire durability and cut precision.

Moreover, the need for regular maintenance can’t be overlooked. Worn-out wires may lead to imprecise cuts, affecting overall production quality. A report indicated that nearly 15% of all wire saw failures are due to improper maintenance practices. Understanding these nuances is crucial for any company aiming to invest in wire saw technology.

When selecting wire saw materials, understanding their benefits is essential. Steel wires are common. They offer durability and strength. However, they may not provide the precision needed for intricate designs. On the other hand, diamond-coated wires excel in cutting fragile materials. They deliver a clean, smooth finish, reducing the risk of chipping. This makes them ideal for delicate tasks.

Ceramic wires are another option. They resist wear and tear effectively. This feature can save time and money in the long run. However, their stiffness can be a drawback. Achieving intricate cuts requires practice. Experimenting with different tensions may help improve results.

**Tips:** Always monitor the wire's tension during cutting. This can prevent snapping. Additionally, maintain a steady pace for better accuracy. Finally, trying different materials helps find the best fit for your needs. This trial-and-error approach can lead to unexpected discoveries.

| Wire Type | Material | Diameter (mm) | Tensile Strength (MPa) | Operating Temperature (°C) | Benefits |

|---|---|---|---|---|---|

| Diamond Wire | High Carbon Steel | 0.7 | 2000 | -20 to 120 | High precision cutting; less waste |

| Ceramic Wire | Zirconia | 0.5 | 1500 | -30 to 100 | Reduced kerf width; minimal thermal impact |

| Alloy Wire | Nickel Alloy | 1.0 | 1800 | -50 to 300 | Excellent flexibility; high durability |

| Steel Wire | Stainless Steel | 0.6 | 1600 | 0 to 250 | Corrosion resistant; versatile applications |

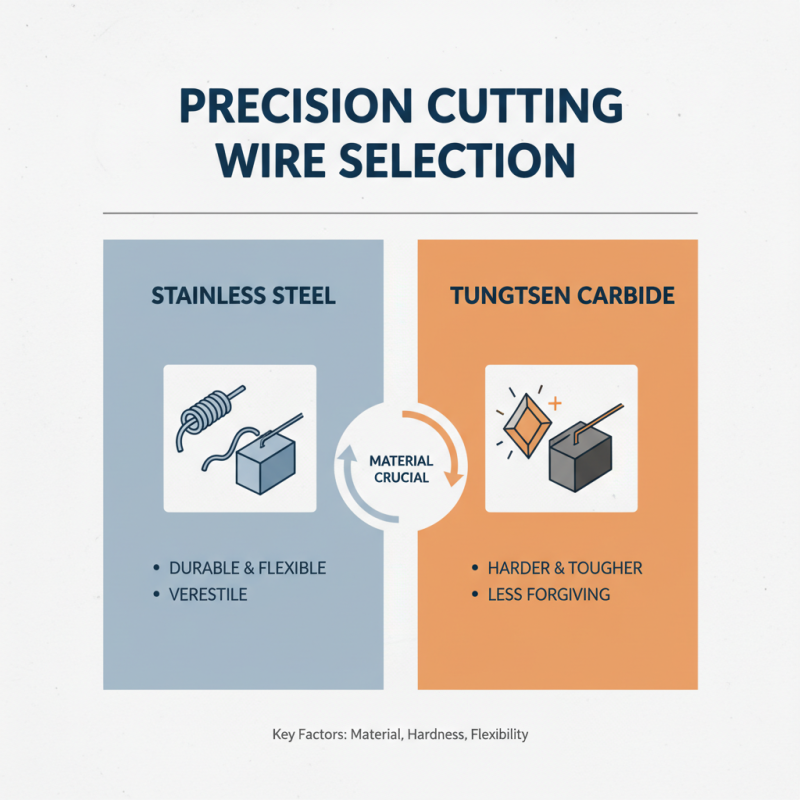

When selecting wire for precision cutting, several factors demand attention. The material of the wire is crucial. Most wires are made from stainless steel or tungsten carbide. Stainless steel is durable yet flexible. Tungsten carbide is harder and can handle tougher materials. However, it tends to be less forgiving during the cutting process.

The thickness of the wire also matters. Thinner wires provide more precision but may wear out quickly. Thicker wires are sturdier but can leave rough cuts. Balancing these aspects can be tricky. You may find that the ideal thickness leads to wastage in some cases.

Another vital aspect is the type of coating. A coated wire can reduce friction, leading to smoother cuts. However, not all coatings are compatible with every material. Testing different combinations becomes essential. It's a process of trial and error. You might realize not every choice leads to optimal results. The exploration of various options is part of finding the perfect fit for your cutting needs.

In the quest for precision cutting, wire saw wires are gaining traction. These cutting tools are essential in various applications, from construction to intricate art projects. Understanding the best options in 2026 can guide users in making informed decisions. Some wires offer durability but may lack flexibility. Others might be too soft for heavy-duty tasks.

Material choice is crucial. Stainless steel is often favored for its strength. However, some users report issues with rust or wear over time. Composite materials have entered the market, showing promise for lightweight and strong alternatives. Yet, they may not perform well in every environment. Testing different wires before settling on one is wise.

Length and thickness also matter. Some prefer thinner wires for detailed work. Others opt for thicker ones that provide more stability. Finding the right balance can be tricky. Users should consider their specific needs before purchasing. This exploration of options reflects the ongoing evolution within the wire saw industry. The landscape is diverse and offers room for improvement.

When using a wire saw, achieving optimal cutting performance involves adhering to best practices that enhance precision and efficiency. Understanding the material properties is crucial. For instance, studies indicate that different wire materials provide varying levels of tensile strength and flexibility, impacting cutting speed. Carbon steel wire, known for its durability, performs well in softer materials. Meanwhile, diamond-coated wires excel with hard substrates, increasing overall production rates.

Another key consideration is wire tension. Optimal tension ensures consistent cutting without excessive wear on the wire or the workpiece. Reports suggest that over-tensioning can lead to premature wire breakage. Conversely, insufficient tension may compromise cutting accuracy. Adjusting tension according to the workpiece thickness can enhance cutting performance, often requiring trial and error for each unique material encountered.

Lastly, maintaining cleanliness is vital. Contaminants can accumulate on the wire, leading to diminished cutting efficiency. Regular cleaning minimizes this issue and maintains the integrity of both wire and workpiece. Yet, operators sometimes overlook this step in favor of immediate productivity. This thoughtless oversight can lead to compromised outcomes, reinforcing the need for diligence in operational practices.