Pawsome-Specializing in vet health products since 2015

Pawsome-Specializing in vet health products since 2015

Choosing the right Wire Saw Blades is crucial for diverse projects. According to John Smith, a leading expert in wire saw technology, "The blade selection can define your project's success." Each project has unique requirements that demand specific blade features.

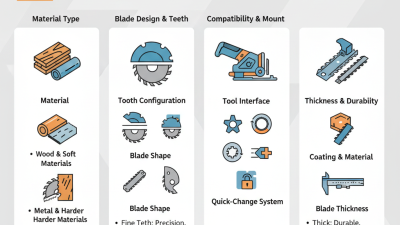

Wire Saw Blades vary in material and design. Diamond-coated blades offer durability and precision for cutting hard materials. However, they can be expensive. Tungsten carbide blades are often more affordable but may lack the same lifespan. Understanding your material and budget is essential.

Reflecting on previous experiences, many have faced challenges with blade performance. Some realized too late that their choices did not match project needs. It’s vital to consider both the technical specifications and practical applications of Wire Saw Blades to avoid potential setbacks. Your choice matters.

When it comes to wire saw blades, understanding the options is essential. Various types cater to different tasks and materials. You may find diamond wire saw blades most useful for cutting hard materials. They provide precision and durability but can be pricier. Consider the operational costs and your budget. Also, note that choosing too high a quality could lead to waste if only low-demand projects are at hand.

Metal wire saws offer another choice. They are often more flexible and affordable, making them great for softer materials. However, they may not last as long as the diamond variety. It’s crucial to balance efficiency and longevity here. In some cases, you might find a wire saw blade that seems perfect, only to realize its limitations during use.

Don’t overlook size and thickness. A thicker blade may cut faster, but it could also create more waste. On the other hand, a thinner blade may require more time. Experimenting with different types and sizes in your projects will help uncover what truly works best. Sometimes, you have to reflect on your choices to find the right fit. The market is rich with possibilities, but each project demands careful consideration.

When selecting wire saw blades, material plays a critical role. Different projects demand specific qualities from blades. For example, steel wire saw blades are common due to their durability. Reports show that steel blades can withstand high tension, thus making them ideal for cutting dense materials. Steel’s versatility is a strong point, but it can also wear out quickly when used on harder surfaces.

Diamond wire saw blades are another option worth considering. They potentially offer higher performance and longer life compared to steel. Studies indicate that diamond blades can reduce cutting time by up to 50%. This efficiency comes at a higher initial cost but can result in savings over time. Yet, they are not necessary for all applications. If your project involves softer materials, the investment might not justify the expense.

Additionally, choosing the right diameter for your wire saw blade is essential. A diameter too large may create unnecessary strain on the saw. Conversely, a small diameter could lead to frequent replacements. Although these guidelines are helpful, every project is unique. Balancing factors like material type, cutting speed, and budget remains a challenge for many fabricators. Understanding what works best often requires trial and reflection.

When evaluating wire saw blades, blade size and length are crucial. A proper choice can significantly enhance cutting performance. For projects requiring precision, the right blade size ensures clean cuts. According to industry reports, a blade length ranging from 20 to 30 inches fits most general-purpose applications. Blades that are too short may force users into awkward angles, compromising accuracy.

In specific projects, the thickness of the material plays a vital role. For instance, blades designed for cutting thick materials often need greater width. A report from the Cutting Tools Association notes that an increase in blade width can improve rigidity and reduce deflection. However, wider blades may limit flexibility, making them less suitable for intricate designs. It's a balancing act.

Working with the wrong blade size can lead to unsatisfactory results. Users may find themselves frustrated by slower cutting speeds or uneven edges. Too much experimentation can waste both time and materials. While some may opt for convenience, understanding the nuances of blade size and length is fundamental for successful projects.

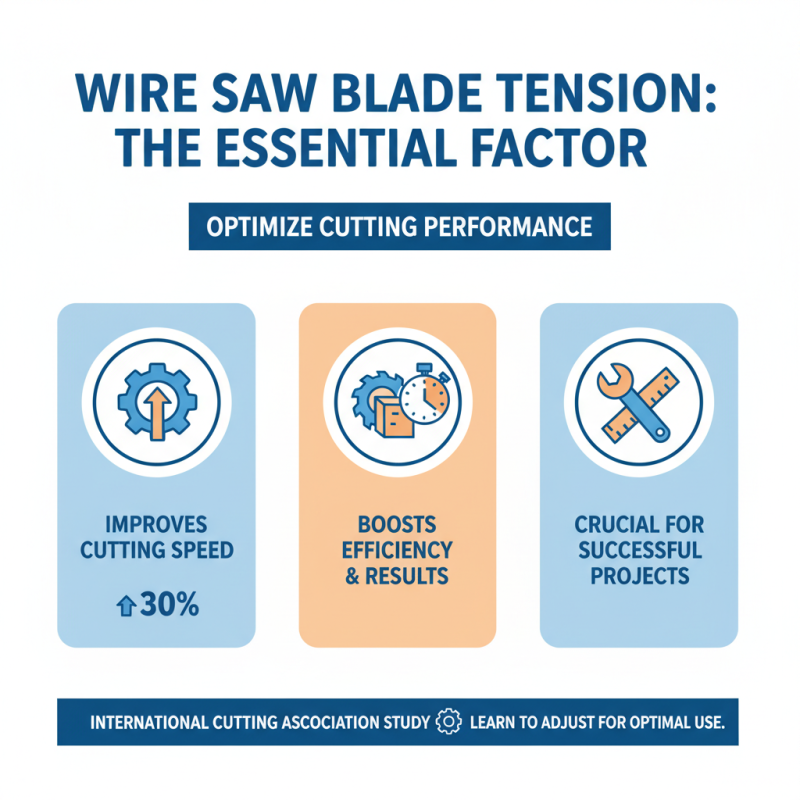

When choosing wire saw blades, blade tension is a crucial factor. Tension directly affects cutting performance and overall efficiency. A study by the International Cutting Association found that optimized blade tension can improve cutting speed by up to 30%. Therefore, understanding how to assess and adjust blade tension is essential for successful projects.

Proper tension allows the blade to maintain contact with the material. Insufficient tension can lead to irregular cuts and increased wear on the blade. Conversely, excessive tension can cause breakage and reduce the blade’s lifespan. According to industry reports, maintaining ideal tension reduces the risk of accidents and enhances worker safety. A balance must be struck between tension and cutting precision, which requires careful calibration.

Testing shows that misjudging blade tension is common in many projects. Workers often overlook this critical setup step, leading to inefficiencies. Regular checks and adjustments based on environmental factors, such as temperature and humidity, are necessary. A lack of attention to detail can cost time and resources. Continuous improvement in blade tension assessment could lead to more consistent results.

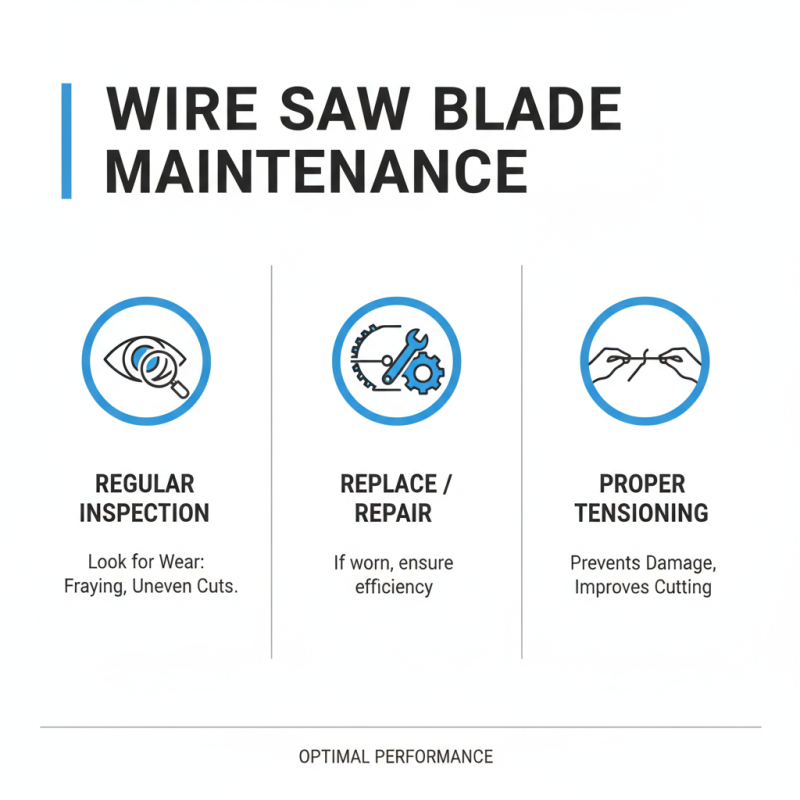

Maintaining wire saw blades is essential for optimal performance. Regular inspection is key. Look for signs of wear, such as fraying or uneven cuts. If you notice these, it may be time to replace or repair them. Proper tensioning can prevent damage. A loose blade can lead to inefficient cutting.

Cleaning is another important aspect. After each use, wipe the blades with a soft cloth. This helps remove debris and prevents rust. A clean blade lasts longer and performs better. Additionally, lubrication reduces friction. Use a suitable lubricant sparingly to ensure smooth operation.

Storage also impacts blade longevity. Store blades in a dry, cool place. Avoid damp areas to prevent corrosion. Using blade covers can protect them from physical damage. Reflecting on your maintenance routine can lead to better practices. Adjust your approach if you notice decreasing performance. Investing time in care will pay off in the long run.