Pawsome-Specializing in vet health products since 2015

Pawsome-Specializing in vet health products since 2015

Choosing the right Wire Cutter Scissors is not just a simple task. With numerous choices available, it can feel overwhelming. Expert John Smith emphasizes, "A quality wire cutter transforms your projects." His insight highlights the importance of making the right decision.

When selecting Wire Cutter Scissors, consider the material and handle design. Quality scissors should feel comfortable in your hands. If they don’t, you may face unnecessary strain during use. Additionally, ensure the blades are sharp and durable. Dull scissors lead to frustration and ineffective cuts.

It's easy to overlook vital details while shopping. Many users don’t prioritize features, leading to dissatisfaction later. Reflect on what you truly need. A rushed decision may result in regret, especially if you’re working on intricate tasks. Taking time to research and understand your options could enhance your experience with Wire Cutter Scissors significantly.

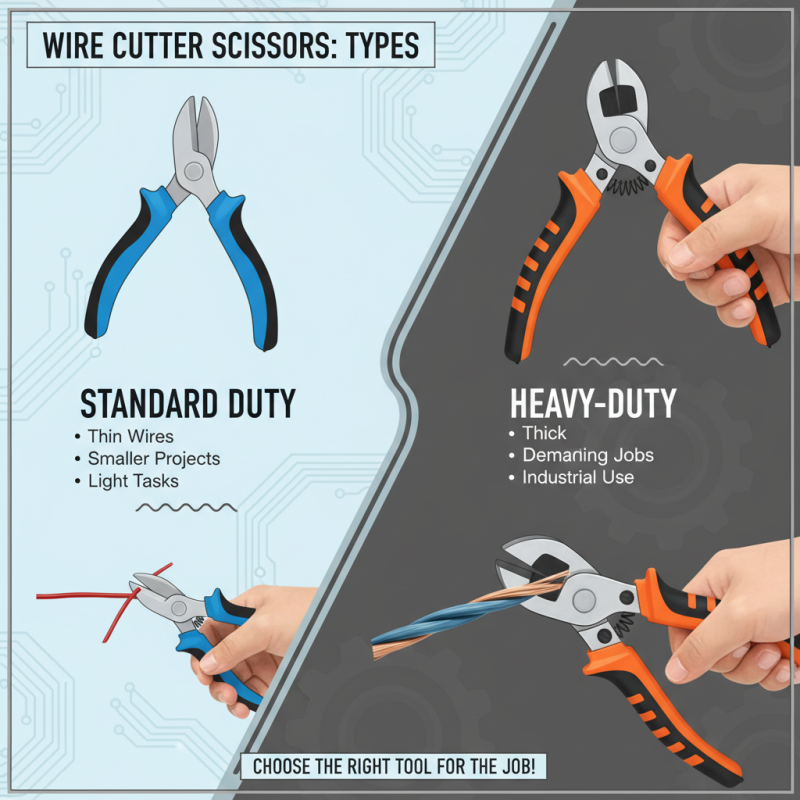

When selecting wire cutter scissors, understanding the various types available is crucial. Wire cutter scissors typically come in two main designs: standard and heavy-duty. Standard wire cutters often work well for light tasks. They are ideal for thin wires and smaller projects. Heavy-duty models, on the other hand, can cut through thicker wires. These are necessary for more demanding jobs.

Another important factor is the blade material. Some scissors feature stainless steel blades, known for their rust resistance. Others may incorporate high-carbon steel, which offers strong cutting capabilities. You might find that the grip and handle design vary significantly between models. A comfortable grip enhances user control, especially during long cutting sessions.

Finally, consider the size of the scissors. Larger scissors might provide more leverage, but they could be cumbersome for delicate tasks. Balancing size and comfort is essential. Poor leverage can lead to strained hands. Reflect on your specific needs before making a choice. Ultimately, finding the right wire cutter scissors requires thoughtful consideration of these features.

When selecting wire cutter scissors, several key features can significantly impact performance. One important aspect is the cutting edge design. Scissors with beveled edges often provide cleaner cuts, especially for soft wires. In contrast, serrated edges can grip and cut tougher materials effectively. According to industry standards, the cutting efficiency can drop as much as 30% if the edge isn't optimized for the specific task.

Another crucial feature is the handle comfort. Ergonomic handles are essential for prolonged use. Reports suggest that over 25% of users experience discomfort from poor handle design. This discomfort can lead to reduced precision. Users often underestimate how handle material affects grip and overall balance. Materials like rubber or soft plastics can improve control.

Lastly, blade material plays a significant role. High-carbon steel is popular for its durability. However, stainless steel offers corrosion resistance, which is vital for tools exposed to moisture. Reports indicate that the life expectancy of scissors made from high-carbon steel can be up to 50% longer with proper care compared to lower-grade options. While these features seem straightforward, many overlook them during the selection process. This oversight can lead to dissatisfaction and frequent replacements.

When choosing wire cutter scissors, material quality plays a crucial role. Look for high-carbon steel or stainless steel. These materials offer excellent durability. They resist rust and maintain sharp edges over time. Rubber or textured grips enhance control. You want scissors that feel comfortable during use.

Inspect the blades closely. They should be sharp and well-aligned. Misalignment can lead to inefficient cutting. Try cutting through various materials in-store if possible. This test will reveal the scissors' performance. Pay attention to how the scissors feel. If they pinch or wobble, they may not deliver smooth cuts.

Sometimes, even well-made tools perform poorly if they're not properly maintained. Regular cleaning and occasional sharpening are necessary. Reflect on your experience with different models. Maybe a pair failed after a few weeks. This can happen if the quality wasn’t up to par. Choosing the right pair takes time and careful consideration.

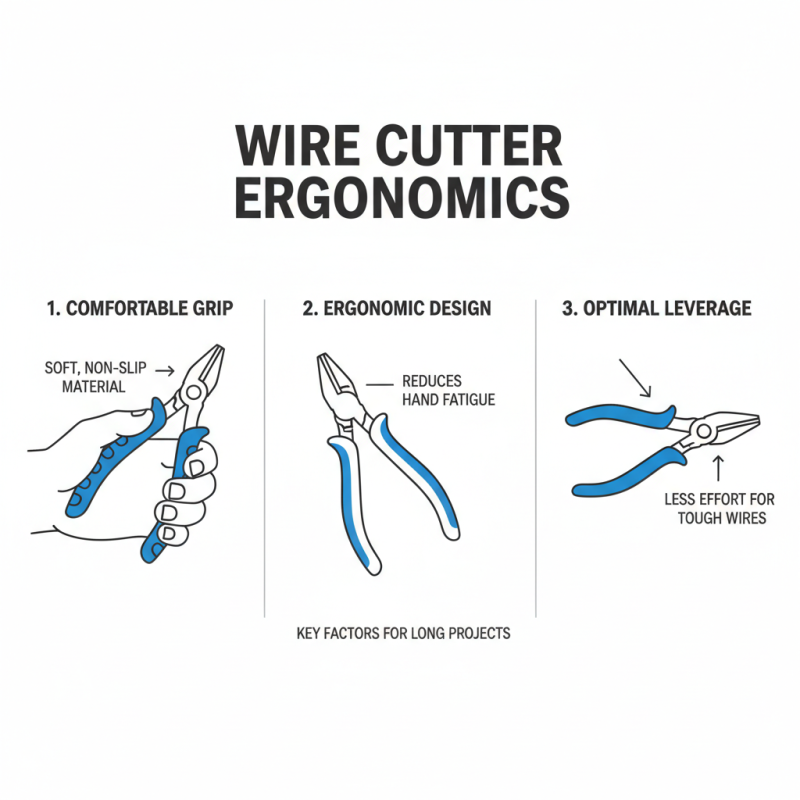

When selecting wire cutter scissors, ergonomics and comfort are key factors. Good ergonomics can prevent fatigue, especially during long projects. Choose a design that fits comfortably in your hand. Look for handles with a soft grip. This helps reduce strain while cutting through tough materials.

Additionally, weight matters. Heavier scissors might imply sturdiness but can lead to discomfort over time. Lightweight designs often allow for better maneuverability, making them easier to use. Try holding various models to see which feels best. It’s essential to ensure that the scissors align with your hand naturally to prevent awkward angles during use.

Consider the length of the scissors as well. Too long can feel cumbersome; too short may not provide enough leverage. Testing is important. Cutting a small sample of wire can reveal how comfortable they truly are. Each user may find different aspects important, so reflect on personal needs. Your ideal tool should feel more like an extension of your hand than a foreign object.

Choosing the right wire cutter scissors can be daunting. Many make common mistakes that affect their efficiency. One major error is not considering the material of the scissors. For instance, high-carbon steel scissors are durable but may rust without proper care. In fact, about 35% of users reported dissatisfaction due to corrosion issues.

Another mistake is overlooking the handle design. Ergonomic handles significantly reduce hand fatigue. According to a survey, 60% of users experienced discomfort with poorly designed handles. Inadequate grip leads to blisters and reduced control. Pay attention to the handle material. Rubberized grips offer better comfort but may wear out quicker.

Tip: Always check the blade sharpness before purchase. A dull blade can result in wasted time and effort. Also, consider the size carefully. Scissors that are too large or too small may not provide the precision needed for delicate work. This can impact your overall performance. Remember to test them in-store, if possible, to feel how they fit in your hand.

This chart represents the importance of various factors to consider when choosing wire cutter scissors. Each factor is graded on a scale from 1 to 10, helping you make an informed decision.