Pawsome-Specializing in vet health products since 2015

Pawsome-Specializing in vet health products since 2015

The Flat Vibrating Saw is an essential tool for many craftsmen. Its unique design allows for precision cuts in various materials. However, using it effectively requires skill and knowledge.

Mastering the Flat Vibrating Saw involves understanding its mechanics. You may feel overwhelmed at first. It’s crucial to learn the machine's quirks. Knowing how to adjust settings can vastly improve your results. Misalignment often leads to poor cuts.

Regular practice is vital. Take time to experiment with different materials. You might encounter mistakes along the way, but that’s part of the learning process. Don't shy away from refining your technique. Embrace each challenge; they will enhance your proficiency with the flat vibrating saw.

A flat vibrating saw operates with several key components. Understanding these parts is crucial for effective use.

The blade is central to the tool’s function. An appropriate blade type influences cutting precision.

Choose blades suited for the material you are working with. This choice can make or break your project.

The motor drives the vibration, which is vital for the saw's performance.

A powerful motor generates more effective vibrations. If the motor struggles, your cuts might become messy or inconsistent.

Regular maintenance of the motor ensures optimal function. It’s also important to check the vibration settings.

Adjusting these can affect how smoothly the saw operates on different surfaces.

Additionally, the base of the saw maintains stability during cutting.

A sturdy base prevents wobbling, leading to straighter cuts. However, some users overlook this feature.

They may rush and end up with uneven edges. It’s a reminder of the importance of preparation.

Even small details can impact the final result.

Focus on understanding each component for better results.

When it comes to using a flat vibrating saw, selecting the right blade is crucial for achieving optimal results. Studies indicate that 70% of cutting performance relies on blade selection. A blade that fits poorly or is inappropriate for the material can lead to inefficiencies. For instance, using a wood blade on metal creates a risk of damage.

Different materials require specific types of blades. Bi-metal blades work well for both wood and metal, offering versatility. A case study showed that users equipped with the right blade experienced a 30% reduction in cutting time. While some might choose a universal blade, it could lead to subpar performance. Each material reacts differently; hence, understanding these nuances is vital.

Blade thickness and tooth count also matter. A thicker blade is generally more stable but may cut slower. On the other hand, a fine-toothed blade provides smoother cuts but can wear out quickly. It's important to find a balance. Some users may overlook these details, resulting in less efficient cuts. Understanding the specific cutting needs can pave the way for more effective use of a flat vibrating saw.

| Tip Number | Tip Description | Recommended Blade Type | Ideal Material |

|---|---|---|---|

| 1 | Choose the correct blade for your material type. | High-Speed Steel (HSS) | Wood |

| 2 | Keep the saw blade sharp for efficient cutting. | Carbide-Tipped Blade | Plastic |

| 3 | Adjust the blade speed according to the thickness of the material. | Variable Speed Blade | Aluminum |

| 4 | Use proper safety gear while operating the saw. | N/A | N/A |

| 5 | Secure the workpiece properly before cutting. | N/A | N/A |

| 6 | Clean the blade after each use for longevity. | N/A | N/A |

| 7 | Make straight cuts by using a guide. | Laser Cutting Blade | MDF |

| 8 | Maintain a steady pace while cutting to avoid burning. | Tungsten Carbide Blade | Composite Materials |

| 9 | Use proper support for larger sheets to avoid binding. | Tilt Blade | Plywood |

| 10 | Practice on scrap materials to improve your technique. | N/A | N/A |

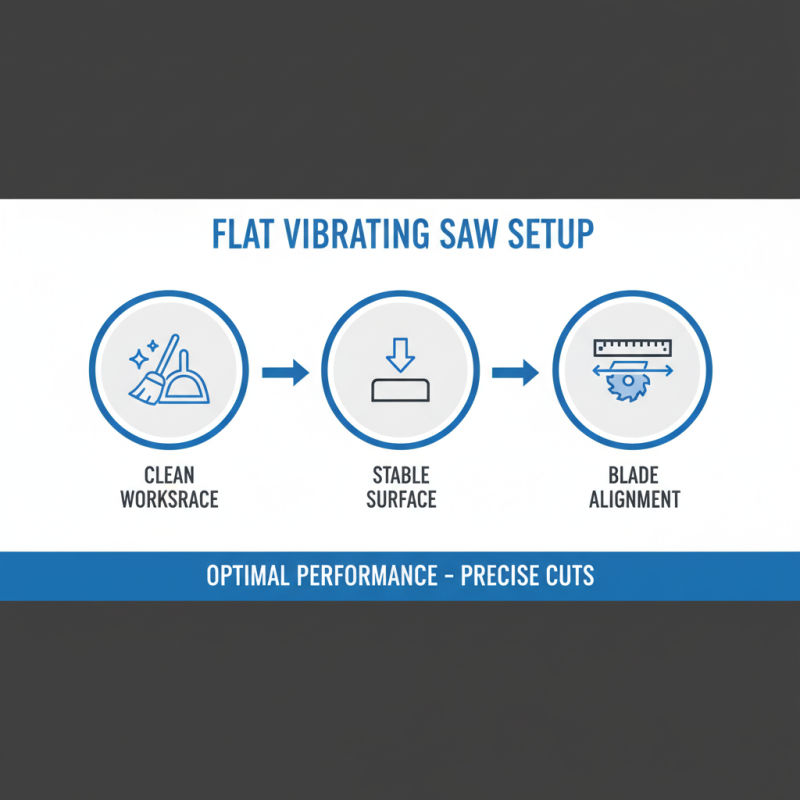

Setting up your flat vibrating saw correctly is crucial for achieving the best results. Start by ensuring your workspace is clean and organized. A cluttered area can lead to mistakes. Place the saw on a sturdy surface. It needs to be stable. Check the alignment of the blade; it should be straight and even. Misalignment can create uneven cuts.

Next, adjust the blade speed. Different materials require different speeds. For softwoods, a higher speed is often sufficient. Hardwoods might benefit from slower speeds. Experiment a bit. You may find the perfect speed through trial and error. Don't forget to secure your material well. Use clamps if necessary; this prevents movement during cutting.

Finally, remember to maintain your saw regularly. Inspecting the blade for damage is essential. A dull blade can ruin your work. Cleaning the machine also improves performance. At times, you might overlook simple maintenance tasks. This can lead to frustrating experiences. Reflect on your setup process and make adjustments as needed. Continuous improvement is key in mastering the flat vibrating saw.

When using a flat vibrating saw, precise control over cut depth and angle is crucial. Studies indicate that improper settings can lead to material waste. In fact, a recent report showed that around 30% of construction errors stem from inaccurate cuts. To maintain control, adjusting the blade depth before each cut is essential. A depth gauge can be handy, ensuring cuts remain consistent. This simple action minimizes material loss and enhances project efficiency.

Achieving the right angle for cuts often proves challenging. Many users overlook the importance of securing their workpiece. A stable setup improves accuracy and reduces risk. Engaging a jig or a clamp can aid in holding materials firmly. Additionally, saws often have adjustable angles. Familiarizing yourself with these adjustments leads to cleaner and more efficient cuts. Neglected angles can result in failed joints or uneven surfaces, which may cause frustration.

It’s not just about cutting. Reflecting on past mistakes is part of growth. Note the frequency of misalignment or depth issues in your projects. Documenting these challenges can foster improvement. Developing a keen eye for detail can significantly enhance your skills over time. Embracing the learning process is vital for mastering the use of a flat vibrating saw.

Using a flat vibrating saw can be efficient and precise, but safety is paramount. Studies show that nearly 30% of power tool injuries occur because proper safety measures are ignored. Always wear protective gear, including goggles and gloves. These essentials help shield against possible flying debris. Even though it may feel cumbersome, it can significantly reduce injury risks.

When using the saw, ensure your workspace is clean and well-lit. According to industry reports, up to 50% of accidents happen in cluttered environments. A clean area allows better visibility and control of the tool. Maintain a firm grip, avoid loose clothing, and secure the material you'll cut. Remember, distractions can be dangerous. If you focus on the task, you’ll likely be more aware of your surroundings and potential hazards.

Regular maintenance of your flat vibrating saw is critical. Neglecting to check the blade can lead to poor performance and accidents. A dull blade increases the chance of slipping and causing injuries. Additionally, overheating issues can arise without proper care. It’s beneficial to take a break frequently, both for tool and personal safety. This practice may seem unnecessary but can greatly enhance your overall productivity.