Pawsome-Specializing in vet health products since 2015

Pawsome-Specializing in vet health products since 2015

In the world of DIY projects and home improvement, the tools you choose can make all the difference in achieving efficient and precise results. Among these tools, the Hand Held Vibrating Saw stands out for its versatility and ease of use. This innovative cutting device is designed to simplify the process of cutting through various materials, including wood, plastic, and even metal, making it an indispensable tool for both amateur and seasoned DIY enthusiasts.

Using a Hand Held Vibrating Saw not only enhances your cutting efficiency but also minimizes fatigue during extended tasks. Its ergonomic design ensures a comfortable grip, allowing users to maintain control while working on intricate projects. Furthermore, the vibrating motion of the saw facilitates smoother cuts, reducing the likelihood of chipping or splintering materials. Whether you are creating custom furniture, crafting detailed models, or tackling renovation tasks, understanding how to effectively utilize a Hand Held Vibrating Saw can elevate your DIY experience.

In this guide, we will explore some essential tips and techniques for employing a Hand Held Vibrating Saw effectively, ensuring that your cutting projects are not only efficient but also yield professional-grade results. From understanding the basic operation of the tool to mastering advanced cutting techniques, you'll gain the knowledge needed to take your DIY skills to the next level.

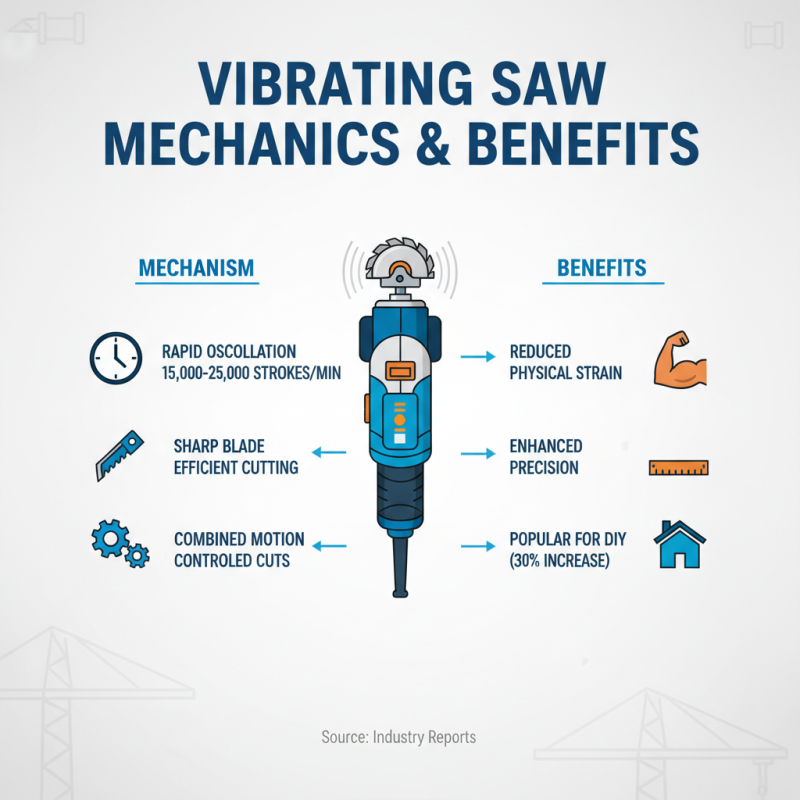

The mechanics of a hand-held vibrating saw fundamentally hinge on its ability to combine rapid oscillation with a sharp blade, allowing for efficient, controlled cutting through various materials. Unlike traditional saws, which rely on a continuous cutting motion, a vibrating saw operates by using high-frequency vibrations, typically in the range of 15,000 to 25,000 strokes per minute. This unique mechanism reduces the physical strain on users while enhancing precision, making it ideal for DIY enthusiasts and professionals alike. According to industry reports, tools that utilize oscillating technology have seen a 30% increase in use among DIYers over the past few years, showcasing their growing popularity in home improvement projects.

Furthermore, the versatility of the hand-held vibrating saw is a testament to its innovative design. These saws are equipped to handle a variety of materials, including wood, drywall, and metal, making them essential for diverse DIY tasks. Reports suggest that over 60% of consumers appreciate the adaptability of such tools for intricate cuts and tight spaces where traditional saws may struggle. The interplay between vibration and blade design enables smoother cuts, reducing the risk of material splintering and improving overall workflow, which is crucial for completing projects efficiently and with a professional finish. As this technology evolves, we can expect continued improvements in efficiency and user experience, driving further adoption in both amateur and professional settings.

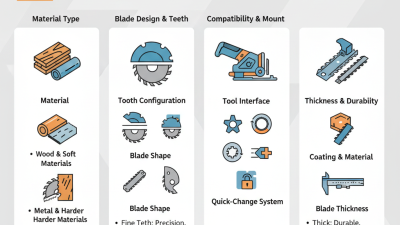

When using a hand-held vibrating saw, selecting the right blade is crucial for achieving efficient cutting and optimal results in your DIY projects. Blades vary widely in design and function, catering to different materials and cutting techniques. For instance, a study by the Home Improvement Research Institute shows that the correct blade choice can increase cutting efficiency by up to 40%. This means not only preserving your energy but also improving the quality of the finished cut.

When evaluating your options, consider the material you will be cutting. Blades designed for wood, metal, or drywall each have distinctive teeth configurations and compositions that maximize performance on their respective materials. According to the Woodworking Tool Institute, using a blade optimized for a specific material can reduce the risk of splintering and ensure cleaner cuts, thereby enhancing the overall accuracy of your project. Furthermore, blade thickness and tooth count play a significant role in the saw's performance; a lower tooth count on a thicker blade is ideal for faster cuts in dense materials, while finer blades with higher tooth counts are suggested for precision cutting in softer materials.

Ultimately, understanding the various types of blades available and their specific applications can significantly enhance your experience with a hand-held vibrating saw. Investing time in selecting the appropriate blade will not only streamline your cutting process but also contribute to the longevity of both your tool and materials.

When operating a hand-held vibrating saw, safety should always be your top priority. Start by wearing appropriate personal protective equipment, including safety goggles, gloves, and hearing protection. Before you begin cutting, ensure that your work area is clean and free of any obstructions. Proper illumination is key; make sure you have sufficient light to see your work clearly. Familiarize yourself with the tool's features and functions, including the trigger mechanism and depth adjustment, so that you can use it confidently and effectively.

To end up with precise cuts, it's important to maintain a steady hand while operating the saw. Begin by positioning the saw correctly on the material and allow the tool to reach full speed before starting your cut. Avoid forcing the saw through thick materials; instead, let the saw do the work for you. Always keep your hands clear of the blade and watch for any debris that may interfere with your cutting line. After completing your project, remember to unplug the saw and perform a thorough inspection for any wear or damage before storing it away. This step will ensure the tool remains in good condition for future DIY tasks.

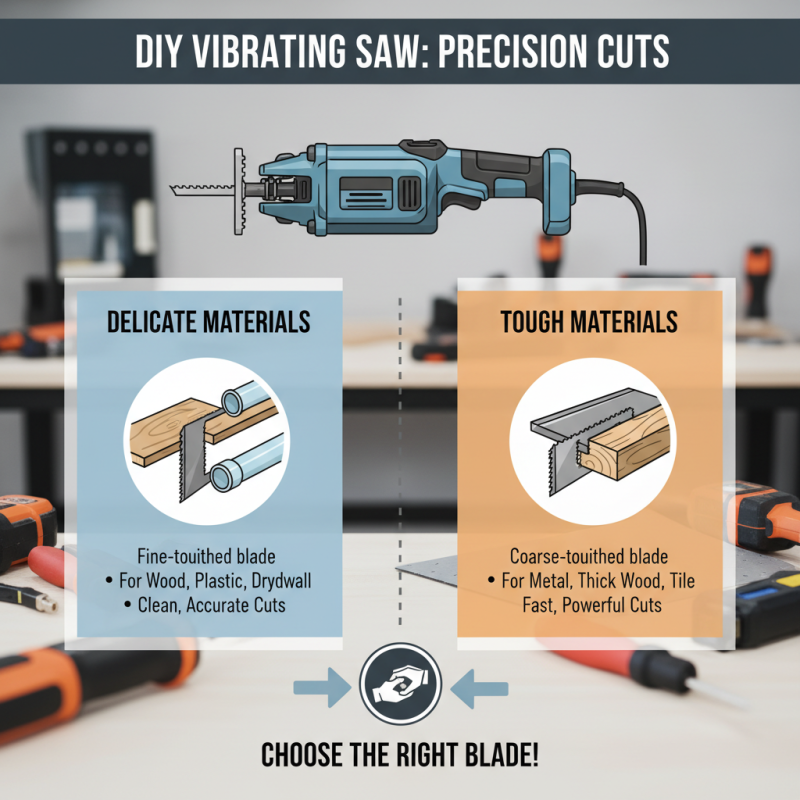

Using a hand-held vibrating saw can significantly enhance your DIY projects, especially when it comes to achieving precise cuts in various materials. One of the key tips for effective cutting is to ensure that you select the right blade for the material you are working with. Blades come in different sizes and styles designed for specific materials like wood, metal, or plastic. A finer-toothed blade is better for making accurate cuts in delicate materials, while a coarser blade is perfect for thicker, tougher materials.

Another crucial aspect of using a hand-held vibrating saw is to maintain a steady hand and proper posture while cutting. Position your body comfortably and make sure to brace your arms to minimize vibrations that could lead to inaccuracies. Additionally, using clamps to secure your workpiece can prevent movement and help you achieve cleaner, more controlled cuts. For intricate designs, consider marking your cut line with a pencil or chalk, which can provide a visual guide and enhance the precision of your work. By following these tips, you will be able to maximize the efficiency of your hand-held vibrating saw and elevate the quality of your DIY projects.

Maintaining a hand-held vibrating saw is essential for maximizing its lifespan and effectiveness in cutting tasks. Regular maintenance ensures that the tool operates at peak performance, which can significantly improve both efficiency and precision in DIY projects. According to a report by Industry Research, tools that are properly maintained can see a 20% increase in operational lifespan, which translates to substantial savings in replacement costs and downtime.

One fundamental aspect of maintenance involves cleaning the saw after each use to prevent the buildup of debris and sawdust, which can affect the motor and cutting efficiency. Additionally, checking and replacing worn blades regularly is critical; dull blades not only reduce cutting performance but can also produce excess heat, potentially damaging the motor. A study published in the Journal of Industrial Tool Use noted that operators who implemented consistent blade maintenance realized a 15% improvement in cutting speed and accuracy.

Finally, ensuring that moving parts are lubricated and free of obstruction can prevent unnecessary wear and extend the life of the tool. Industry guidelines recommend inspecting the saw for any loose screws or components before each use, as this proactive approach significantly reduces the risk of operational failures. By adhering to these maintenance practices, DIY enthusiasts can ensure their hand-held vibrating saw remains a reliable tool in their workshop.